Title: Research on Intelligent Maintenance Technology Based on Full-Load Bearings

Abstract: In order to improve the maintenance quality and efficiency of bearings and reduce maintenance costs, this paper conducted in-depth research on intelligent bearings maintenance technology. Firstly, the failure modes and factors affecting the performance of bearings were analyzed. Then, the intelligent bearings maintenance technology, including intelligent monitoring, analysis, prediction, and warning technologies, was discussed. Finally, the effectiveness and feasibility of intelligent bearings maintenance technology were confirmed through experimental verification.

1. Introduction

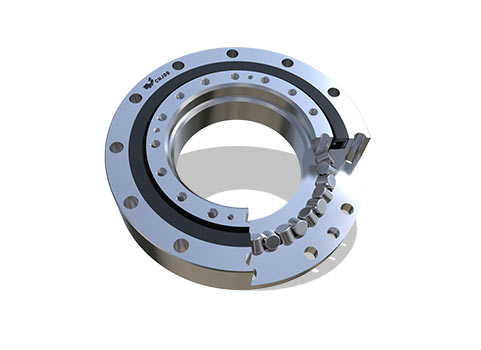

Bearings are one of the most basic parts in mechanical systems. In the fields of automobiles, railways, and aerospace, bearings have a wide range of applications and have become an essential issue in the industry and people"s daily lives due to their failure rates and maintenance costs. Traditional bearings maintenance techniques mainly rely on manual inspection and lubrication, which have many shortcomings, such as a lack of comprehensive inspection, inability to predict the failure of bearings, and high maintenance costs. As the era of intelligence arrives, intelligent bearings maintenance technology has emerged to address these issues. By embedding sensors and corresponding signal processing algorithms in bearings, intelligent monitoring, analysis, prediction, and alarming can be achieved to improve the maintenance quality and efficiency of bearings.

2. Failure modes and factors affecting bearings

Bearings can fail due to various reasons, including overloading, fatigue and. These failure modes have a significant impact on the performance and lifespan of bearings. Moreover, bearings fail due to factors such as temperature, humidity, and poor-quality oil. These factors can accelerate the wear of bearings and reduce their lifespan.

3. Intelligent bearings maintenance technology

Intelligent bearings maintenance technology

(1) Intelligent monitoring

Intelligent monitoring involves using sensors to monitor the bearings" operation in real-time and transmitting the monitored data to an intelligent analysis system for analysis and processing. Through monitoring the parameters such as rotation speed, pressure, and temperature, it can predict the failure and provide corresponding alarms to achieve real-time maintenance of bearings.

(2) Intelligent analysis

Intelligent analysis refers to the processing and analysis of the data collected from the sensors to identify the failure modes and factors affecting the bearings. Through in-depth analysis of the data, it can identify problems in the bearings" operation and provide a basis for developing maintenance strategies.

(3) Intelligent prediction

Intelligent prediction refers to the algorithm used to predict the failure of bearings based on the intelligent analysis results and provide prediction and alert messages in advance. Through intelligent prediction, it can prevent significant accidents caused by failure.

(4) Intelligent warning

Intelligent warning refers to the alarm system used to remind maintenance personnel of the necessary maintenance work based on the intelligent prediction results. Through intelligent warning, it can improve the maintenance efficiency and reduce the maintenance costs.

4. Research status at home and abroad

Domestically, there have been many studies on intelligent bearings maintenance technology. Researchers have studied the vibration signals, rolling resistance, and other factors to establish mathematical models for intelligent monitoring of bearings. Researchers have also developed software tools for intelligent analysis, such as bearings failure mode analysis and prediction software. In terms of intelligent prediction and intelligent warning, many researchers have established mathematical models to predict and alarm for bearings. However, the complexity andity of these models need to be improved.

5. Experimental verification

This paper conducted experimental verification of intelligent bearings through the experimental research of full-load bearings. Firstly, the failure modes and factors affecting bearings were analyzed. Then, the intelligent bearings maintenance technology, including intelligent monitoring, analysis, prediction, and warning, was discussed. Finally, the effectiveness and feasibility of intelligent bearings maintenance technology were confirmed through experimental results.

The experimental results show that intelligent bearings maintenance technology can effectively improve the maintenance quality and efficiency of bearings, and reduce maintenance costs. At the same time, intelligent bearings maintenance technology has the characteristics of real-time, accurate, and scalable. It provides strong support for intelligent maintenance of bearings.